Home / Solution

WE DELIVER INNOVATIVE SOLUTIONS TO

THRIVES YOUR PRODUCTIVITY GLOBALLY.

NACSYST offers customized solutions that fulfil your requirements which helps to increase your productivity.

Our Services

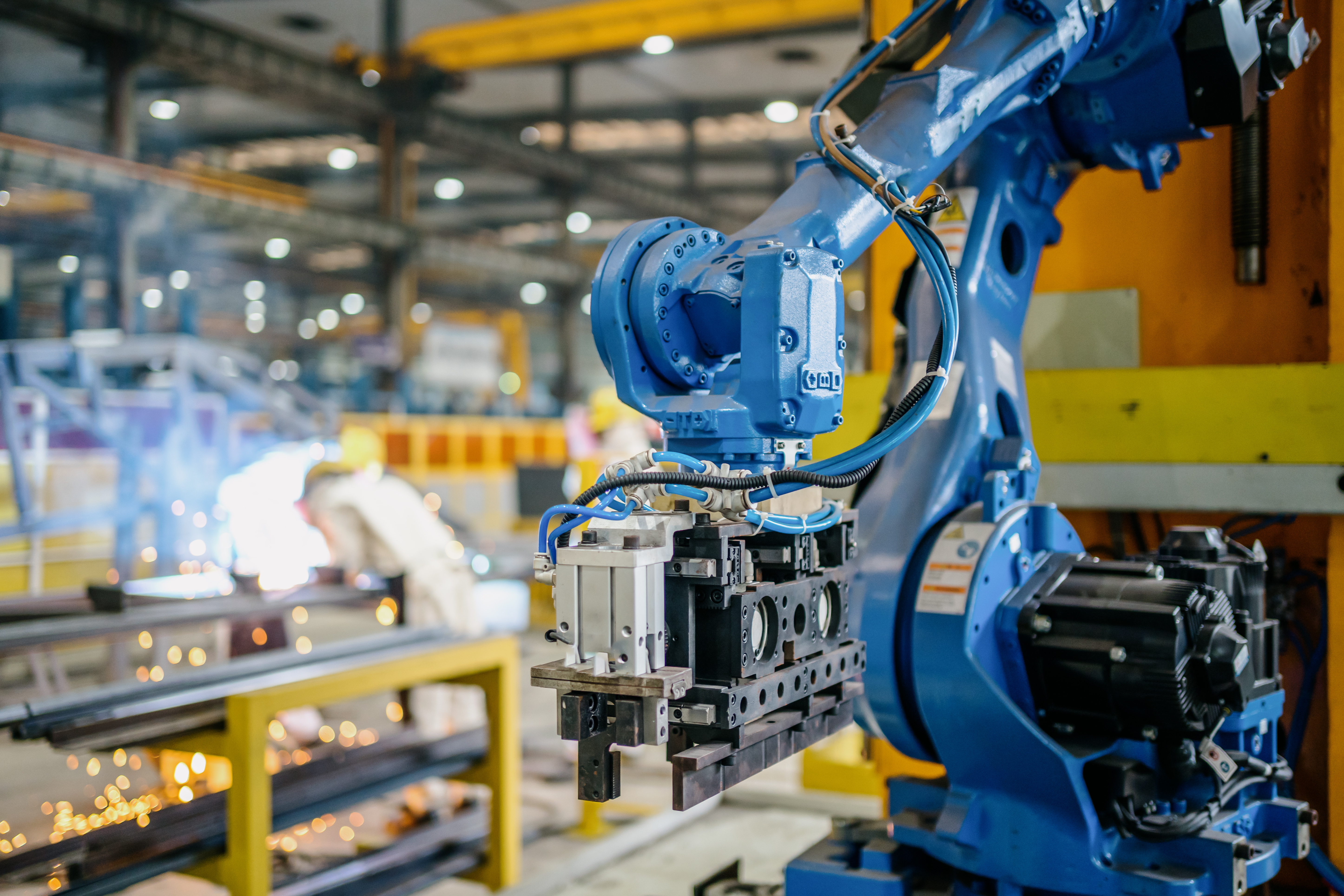

WELDING SYSTEM

Robotic welding was designed to ease the production efforts for welders and facilities throughout the industry. where technology continues to advance, the manufacturing industry has taken advantage of robotic welding benefits. NACSYST design and build complete turnkey welding automation packages. We’re unmatched in creating custom welding automation solutions for automotive industry customers in product manufacturing. NACSYST has taken modern welding automation to the next level with features such as automatic welding programming, collision avoidance, robotic vision, and adaptive welding. We thrive when solving complex welding automation challenges. Our welding system solutions comprise spot welding and mig robotic cell, welding spm’s and manual welding fixtures.

HANDLING SYSTEM

If you want to move your product between machines to machine, be packaged and crated, or if you need a automated feeding system, NACSYST support you to create a intelligent automated as well as semi automated material handling solution. NACSYST offers comprehensive safe & reliable material handling systems to manufacturers. We supplies automakers with automation and labor-saving systems that cover the entire process. We work with strategies and apply latest advances in technology to increase production. We take a holistic approach to safety. Our innovative safety solutions improve the functional operation of system or equipment while helping to increase more safety, efficiency, and productivity. Our material handling solutions include conveyors with robotics, gantry systems, collaborative and industrial robots, automated-guided vehicle integrations, and more.

CONVEYOR SYSTEM

Now a day manufacturing products demand is increasing, to complete that time line manufacturers required conveyor systems for uninterrupted transportation. NACSYST offers custom designed conveyors for manufacturer in automotive applications. We are works with you to determine the conveyor equipment that is right for your situation. Whether you need simple sections of gravity conveyor or fully automatic or semi-automatic, NACSYST can help find the perfect solution for you. We often integrated with other devices such as scanners, sorters, label print and apply devices, case sealers, in-line weigh scales, palletizers, and robotics.

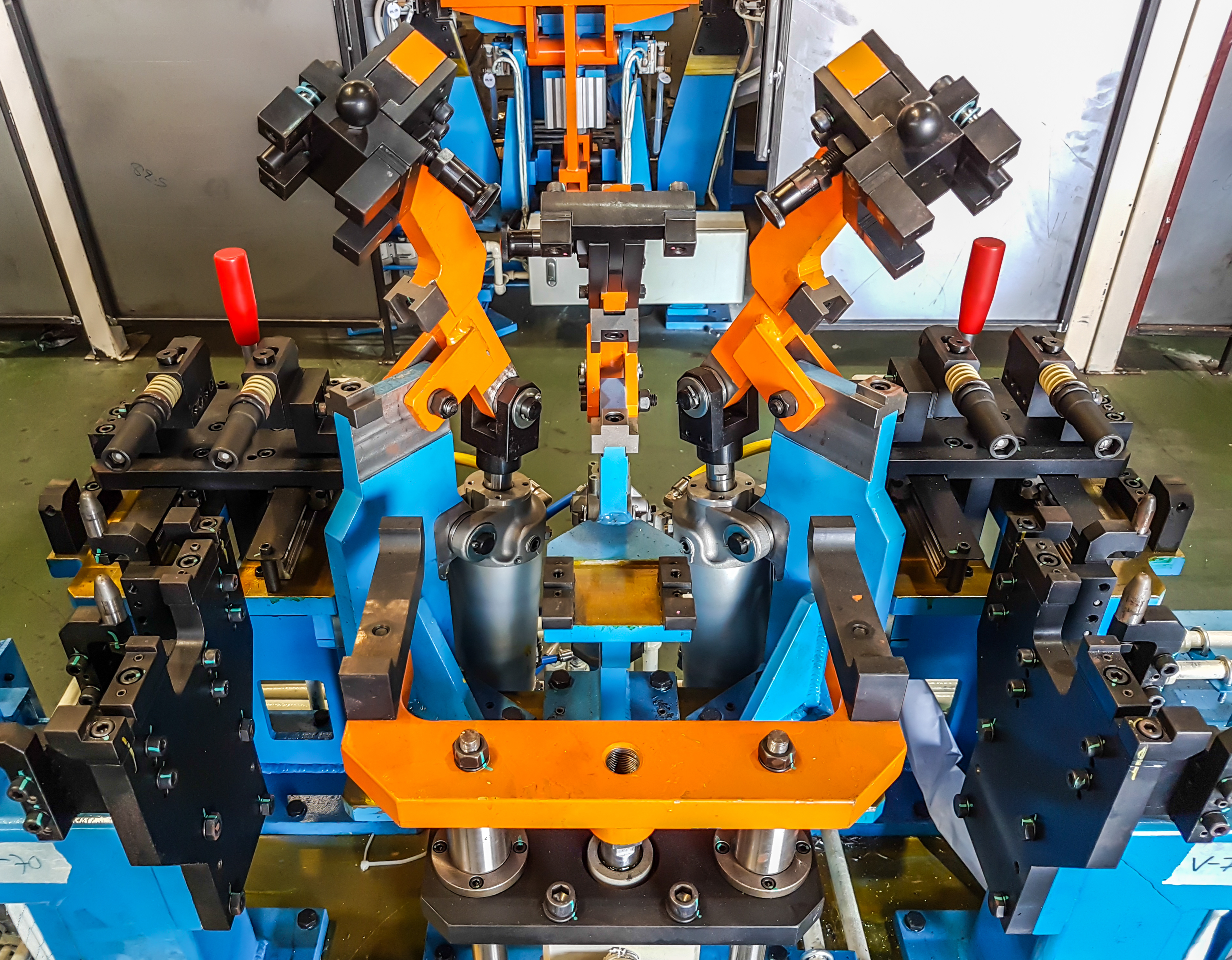

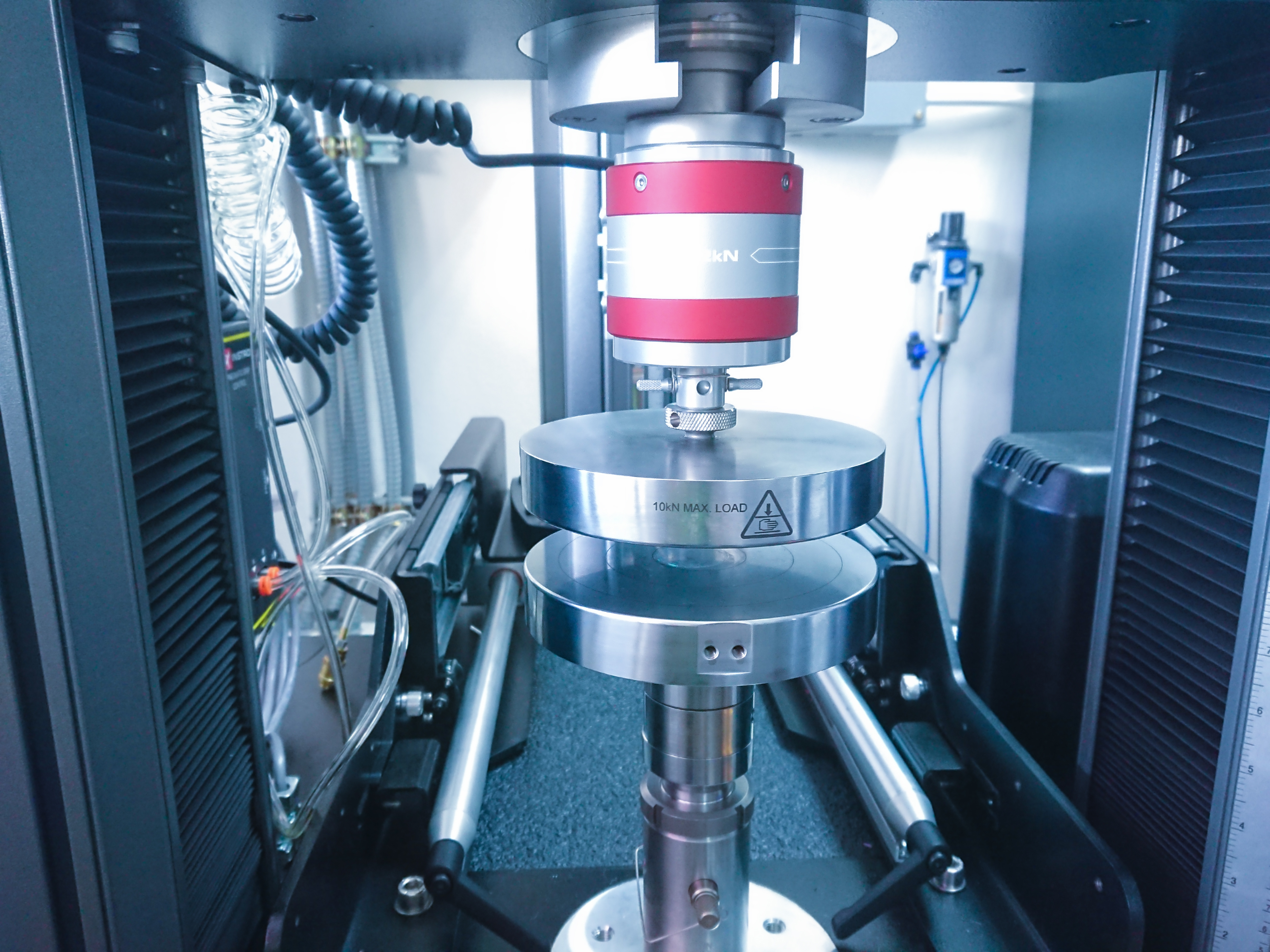

SPECIAL PURPOSE MACHINE

Special Purpose Machine (SPM’s) are those machine which not available of the shelf. These are not covered in standard manufacturing programs. The Special Purpose Machines and Automated machines are intentionally designed to operate continuously for 24 hours a day with the least supervision. These machines are usually product specific and need to be designed and developed differently for each specific requirement. In the production method, there is always a need and scope to improve the quality of the product and also focus on the other factors like to minimize the rejection and increase the productivity. NACSYST offers these type of machine to manufacturers to achieve optimum output. Our SPM’s solutions contains leak test, drilling system, inspections machines and other customized spm’s. We often integrated with other devices such as Printer, Scanner, Vision system, Marking machines etc.

JIG AND FIXTURES

The key to successful industrial automation is Programming. An incorrected programmed can result in costly downtime and can even cause damage to equipment or whole system. NACSYST offer software solution which is very easy to use, understand and helpful to reduce your breakdown time. mostly we provide software solution for Automotive industries. NACSYST has qualified professionals with programming experience of Programable Logic Controller (PLC), Human Machine Interface (HMI), Supervisory Control And Data Acquisition (SCADA),Industrial Robot Programming, Servo Motors Applications and VFD’s.